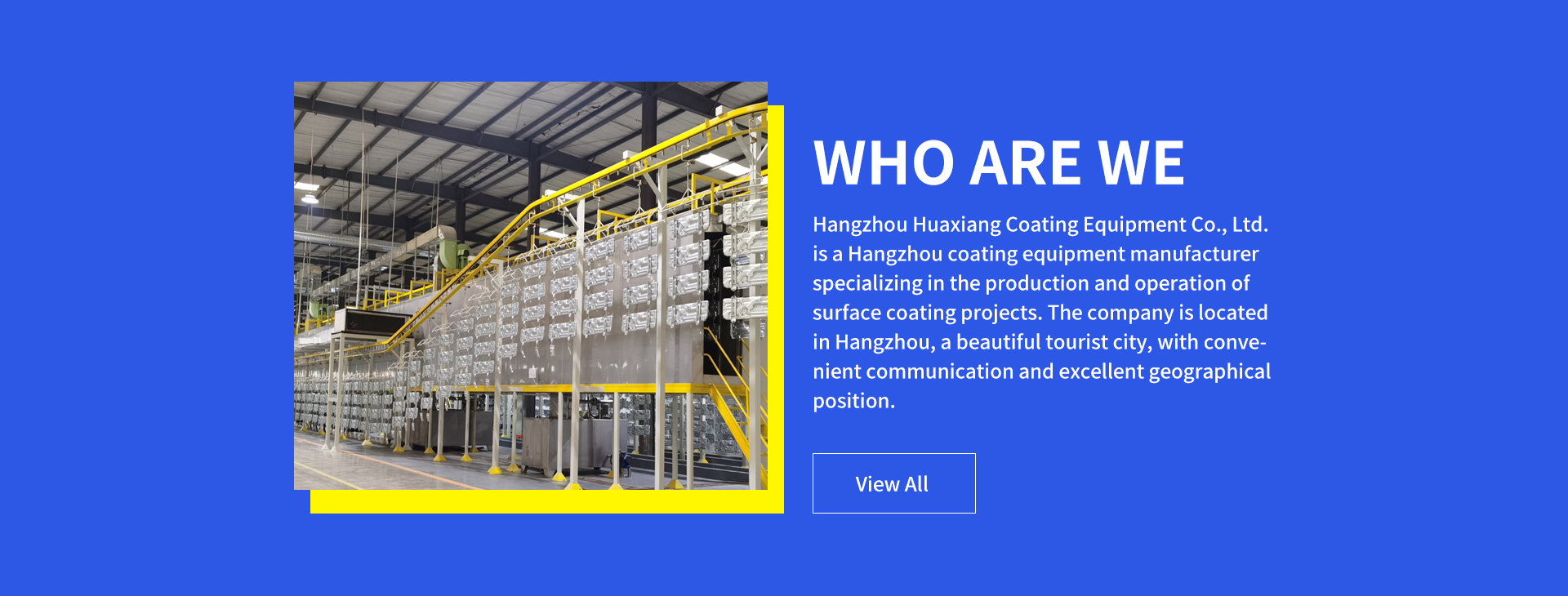

Introduction to China Powder Coating Machines

China Powder Coating Machines are renowned for their affordability, advanced technology, and adaptability to diverse industrial requirements. Manufactured by leading suppliers, these machines utilize electrostatic principles to apply durable, eco-friendly coatings on metal surfaces, ranging from automotive parts to architectural components. With competitive pricing (starting at $3,000) and adherence to international standards like CE and ISO, China-made systems offer high efficiency, low maintenance, and robust performance. They are widely exported to markets in Europe, North America, and Southeast Asia, cementing China’s role as a global hub for powder coating machine innovation and production.

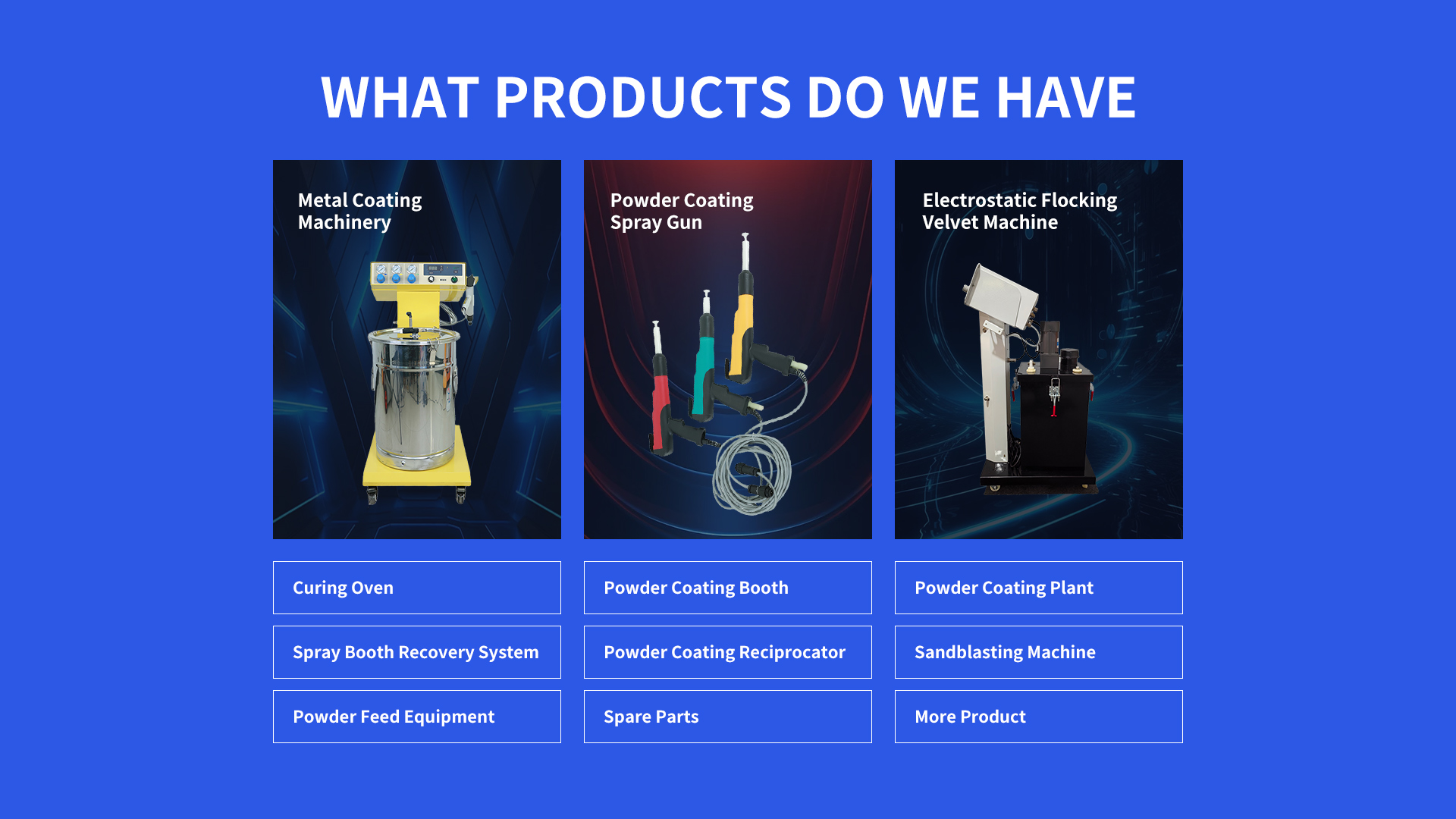

1. Components of China Powder Coating Machines

A typical China Powder Coating Machine includes:

Electrostatic Spray Guns: Manual or automatic models with adjustable voltage (30–90 kV) for precise application.

Powder Feeding System: Hopper, fluidizing chamber, and pumps to ensure smooth material flow.

Curing Ovens: Electric or gas-powered units with temperature ranges of 150–250°C.

Recovery Systems: Cyclone or cartridge filters to reclaim 90%+ oversprayed powder.

Leading China powder coating machine manufacturers integrate IoT-enabled controls, modular designs, and energy-saving technologies to enhance productivity.

2. Applications of China Powder Coating Machines

These machines serve industries such as:

Automotive: Coating wheels, engine parts, and chassis for OEMs and aftermarket suppliers.

Home Appliances: Applying scratch-resistant finishes on refrigerators, microwaves, and washing machines.

Construction: Protecting steel beams, pipelines, and aluminum window frames from corrosion.

Other sectors include agricultural machinery, furniture manufacturing, and electronics enclosures, where cost efficiency and rapid turnaround are critical.

3. Design Considerations for China Powder Coating Machines

Key design priorities include:

Compliance: Meeting international safety standards (e.g., CE, UL) for global exports.

Energy Efficiency: Insulated ovens, heat recovery systems, and low-power electrostatic guns.

User-Friendliness: Intuitive touchscreens, multilingual interfaces, and quick-change powder systems.

Durability: Stainless steel frames and corrosion-resistant coatings for long-term use.

These features ensure China powder coating machine reliability in demanding environments.

4. How to Select a China Powder Coating Machine

Evaluate the following:

Production Needs: Opt for automated lines for high-volume tasks or manual systems for small batches.

Material Compatibility: Verify compatibility with substrates like steel, aluminum, or pre-treated metals.

Supplier Reputation: Partner with certified China powder coating machine suppliers offering warranties and after-sales support.

Budget: Prices range from 3,000(basicmanualunits)to200,000+ (fully automated lines). Factor in shipping and customs costs.

5. China Powder Coating Machine Q&A

Q: How to ensure consistent coating quality?

A: Regularly calibrate spray guns and follow China powder coating machine maintenance guidelines from suppliers.

Q: Are Chinese machines safe for hazardous environments?

A: Yes, many models include explosion-proof designs compliant with China powder coating safety protocols.

Q: What makes China machines cost-effective?

A: Lower labor and production costs, bulk purchasing options, and China powder coating machine price advantages.

Q: Do suppliers provide technical training?

A: Reputable suppliers offer on-site or virtual training for China powder coating machine operation.

Q: Can they handle custom coatings?

A: Yes, modular designs allow integration of specialty powders like anti-bacterial or thermal-resistant types.

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com